Empowering Businesses with Innovative Solutions

Yupek Solutions delivers cutting-edge technology services and consulting to help your business thrive in the digital age.

About Us

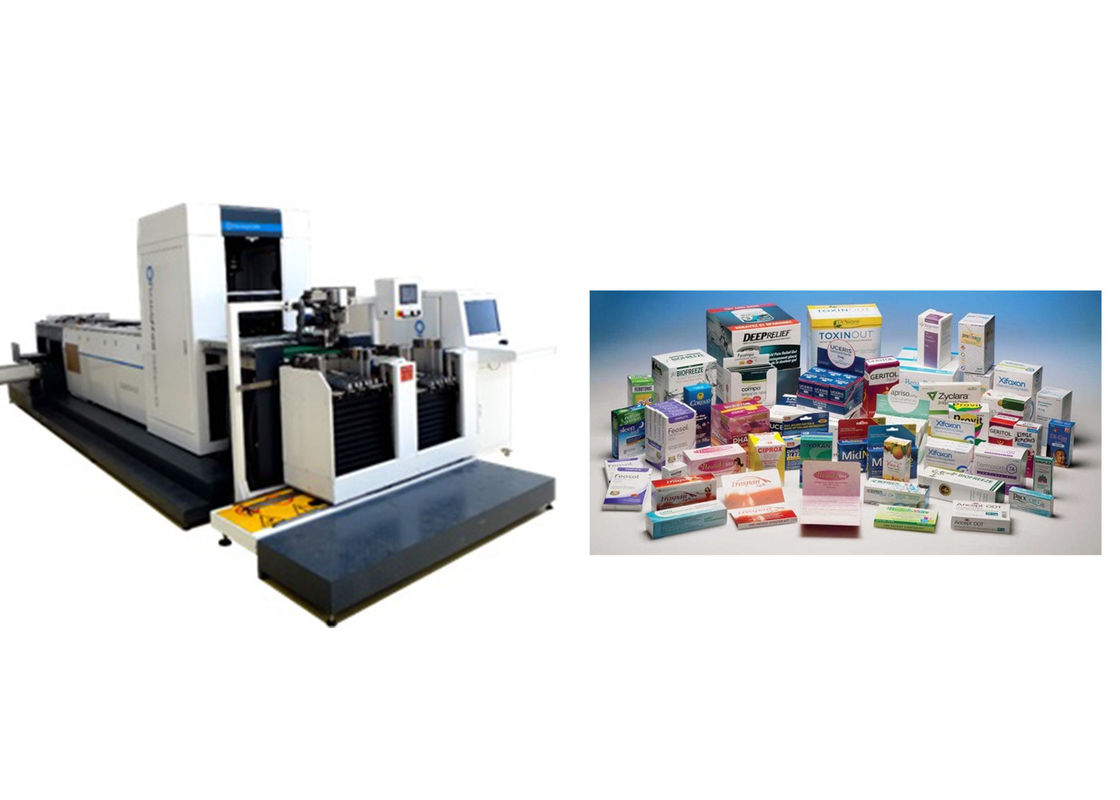

Yupek Solution is a dynamic and forward-thinking company specializing in the trading of industrial machinery and technical services, with a core focus on prepress and postpress solutions for the printing and packaging industries.

Founded on the principles of quality, precision, and innovation, Yupek Solution is committed to delivering high-performance equipment and expert services that empower businesses to streamline their operations and elevate production standards.

Our Products

High-quality industrial inspection machines and vision systems

Shark-500 Printing Inspection Machine with Quality Control Vision Systems

Model: FS-SHARK-500

Shark-500 Printing Inspection Machine and Vision Quality Control System. Focusight's FS-SHARK-500 delivers high-speed, high-accuracy inspection for printing and foil defects, separating good and defective sheets to improve process efficiency and eliminate manual inspection.

Shark-650 Printing Inspection Machine — Focusight Inspection Machine for Folding Cartons

Model: FS-SHARK-650

Focusight FS-SHARK-650 is a high-performance printing inspection system for folding cartons, pharmaceutical packaging, luxury goods and more. It combines 4K/8K cameras, advanced LED lighting and high-speed image analysis to detect print, foil and surface defects at up to 250 m/min.

Gecko 200 Vision Inspection Equipment — Electronic Tag Print Inspection System

Model: FS-GECKO-200

Electronic Tag Printing Inspection Machine, Gecko 200 — specially designed for clothing/garments tags inspection. Focusight's system detects printing and finishing defects and automatically rejects defective tags at high speed.

Machine Vision Inspection Systems for Maximum 500mm Size Electronic Box Cartons

Model: FS-GECKO-500

Focusight FS-GECKO-500 is a high-speed machine vision inspection system designed for electronic box cartons and luxury packaging. It identifies printing and finishing defects automatically using high-resolution cameras and LED lighting.